Fire safety plays a key role in every facility, both industrial and residential. A properly selected and constructed sprinkler system not only protects people’s lives, but also minimizes material losses that may result from a fire. Modern sprinkler systems are not only technology, but also a guarantee that in a crisis situation, protective measures will start automatically and effectively. Thanks to our solutions, you can be sure that your facility is prepared for any eventuality, regardless of its specificity.

How Does a Sprinkler System Work? Key Information

The sprinkler system operates on the principle of automatic fire detection and extinguishing, which is why it is one of the reliable fire protection systems. Its operation is based on the bursting of the sprinkler ampoule under the influence of an increase in temperature. After exceeding a certain thermal threshold, the system releases water from distribution pipelines, effectively extinguishing the source of the fire. The elements of the system, such as the fire water tank, the control and alarm valve, or the pipe network, are precisely designed to ensure an immediate response to the appearance of flames. Additionally, the system operates selectively – only those fire sprinklers located in the danger area are activated. This prevents flooding of rooms that have not been affected by the fire, which is particularly important in buildings such as high-bay warehouses or server rooms. It is also worth paying attention to the variety of installation types. This strategy allows you to adapt the system to the specific needs of the facility. Our offer includes both a wet sprinkler system, ideal for places with a constant temperature, and a dry sprinkler system, designed for buildings exposed to negative temperatures.

Types of sprinkler systems and their applications

The variety of sprinkler systems allows for their versatile use in facilities with different requirements. The most popular solution is the wet sprinkler system, in which the pipelines are constantly filled with water. This is an ideal solution for buildings with stable temperature conditions, such as offices, shopping malls or hotels. In places exposed to low temperatures, such as refrigerated warehouses or underground car parks, a dry sprinkler system is used, in which the pipelines are filled with compressed air or nitrogen. When the control and alarm valve is activated, water is injected into the pipes, which allows for rapid extinguishing of the fire. Specialised applications require pre-action sprinkler systems. Such systems minimise the risk of accidental flooding and are particularly recommended in facilities such as libraries, museums or server rooms, where water can cause irreversible damage.

Why is it worth trusting fire protection installation specialists?

Choosing the right partner for the design and installation of fire protection systems is essential for the safety of the facility. Our company offers a comprehensive approach to each project, taking into account the specifics of the building, legal requirements and individual customer needs. Thanks to our experience in installation of fire protection systems, we guarantee that every detail, from control and alarm valve to distribution pipelines, will operate in accordance with the highest standards. We operate in accordance with PN-EN, NFPA and VdS standards, which is why we guarantee compliance with the requirements of insurers and legal regulations. By working with us, you can count on full support – from the design stage, through professional installation, to service and modernization.

Sprinkler system type and building requirements

Every building has different needs related to fire protection, so it is important to choose the right type of installation. For buildings with stable temperature conditions, such as offices or shopping malls, the ideal solution is a wet sprinkler system. On the other hand, in buildings exposed to low temperatures, such as cold stores or outdoor warehouses, a dry sprinkler system will work well. Buildings where water could cause damage have special requirements – we recommend pre-action systems there. For large facilities, such as production halls or high-bay warehouses, we use advanced sprinkler systems that ensure maximum effectiveness.

Sprinkler installation stages – from design to implementation

Installation of a sprinkler system is a complex process that requires precise planning, technical knowledge and compliance with the highest safety standards. Each stage of implementation is crucial for the proper functioning of the system. Below are the detailed stages of installation:

Step 1: Needs analysis and facility audit

The first step is to thoroughly understand the specifics of the facility, its purpose, and environmental conditions. We conduct a sprinkler system audit, assessing potential threats and building requirements. At this stage, we identify the appropriate type of system, such as a wet sprinkler system for buildings with constant temperatures or a dry sprinkler system for buildings exposed to freezing. We also analyze the available water pressure, which can affect the system’s performance.

Step 2: Designing the sprinkler system

Based on the collected data, we begin the detailed design of the sprinkler system. We develop the pipeline layout, the arrangement of fire sprinklers and other elements, such as alarm control valves and a fire water tank. The design also takes into account sprinkler system parameters, such as water flow and range of operation. All plans comply with VdS, NFPA and PN-EN standards to ensure maximum safety and reliability.

Step 3: Prefabrication of elements

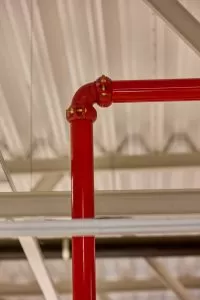

Before assembly on site, we prepare all the necessary components. Distribution pipelines, fire pumps and other components are manufactured in our prefabrication plant. This allows us to guarantee the highest quality of workmanship and precise adjustment to the project. Prefabrication also allows for shorter assembly times on site and reduces any potential interruptions in the facility’s operation.

Step 4: On-site installation

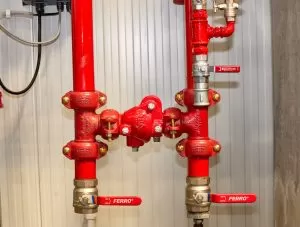

At this stage, we begin installing the elements in the building. We install pipelines, connect fire sprinklers, install alarm control valves and integrate the system with the main water supply, e.g. with a fire water tank. In the case of a dry sprinkler system, we also install air compressors that provide pressure in the pipelines. Each element is precisely installed in accordance with the design to ensure its full functionality.

Step 5: Testing and technical acceptance

After the installation is complete, the system undergoes detailed tests. We check the tightness of pipelines, the efficiency of the fire pump and the system’s response to temperature increase. We also test the operation of alarm control valves and the correctness of the layout and operation of sprinklers. All tests are documented, and the system is put into service after achieving full compliance with standards. We carry out each of these stages with the utmost care, minimizing the risk of delays and the impact of the work on the functioning of the facility. Thanks to our experience and modern technologies, installation of fire protection systems is an efficient, effective and fully tailored process to the customer’s needs.

Sprinkler system inspections and maintenance – a way to ensure reliability

Regular inspections and maintenance of the sprinkler system are essential to ensure its reliable operation in every situation. The fire protection system is a system that operates in the background of everyday activities, but its effectiveness is most important in the event of a threat. Neglecting regular inspections can lead to system failure, which in the event of a fire could result in huge material losses and even a threat to human life.

Why are inspections so important?

- Ensuring full technical efficiency

Sprinkler systems consist of many precision components, such as alarm control valves, sprinklers and distribution pipelines. Each of these components must function flawlessly so that the system can effectively respond to fire hazards. Regular inspections allow even minor faults to be detected before they affect the system’s operation. - Preventing corrosion and contamination

In water installations such as wet sprinkler systems there is a risk of sediment or rust building up in the pipes. These contaminants can block the flow of water, reducing the effectiveness of the system. During inspections, we check the condition of the pipes and, if necessary, clean them. - Meeting legal and insurance requirements

Standards such as VdS, PN-EN and NFPA require regular inspections of sprinkler systems to ensure they meet safety standards. In addition, many insurance policies make compensation in the event of a fire dependent on proof of periodic inspections of the system. - Extending the life of the system

Proper maintenance of the sprinkler system allows for extending its service life. Regular inspection and replacement of worn components, such as fire sprinklers, minimize the risk of serious failures that could involve expensive repairs or the need to replace the entire system.

Sprinkler Systems – Your partner in reliable fire protection!

By choosing our services, you are investing in the safety of your facility and the certainty that the fire protection system will work efficiently when it is most needed. The fire protection systems we provide are a combination of advanced technology, precise workmanship and the highest safety standards. We carry out each project with an individual approach, taking into account the specifics of the building and the client’s requirements, which allows us to create systems perfectly tailored to various needs. Thanks to the experience of our team, you can be sure that both the design and the installation and subsequent service will be carried out with full professionalism. Trust us and secure your facility comprehensively – contact us today to learn more about the offer and start cooperation with a partner who will take care of your safety in every situation.