Production in any industry is a process in which every minute of downtime can mean significant financial losses. That is why more and more companies decide to use modern fire protection solutions, such as sprinkler systems, which allow for effective response to threats and ensure continuity of production processes. What benefits can be achieved by implementing them and how do they affect the minimization of interruptions? You will find answers to these questions in the article below.

How do sprinkler systems affect the continuity of production processes?

Sprinkler systems are one of the most effective tools for fire protection. Their operation is based on rapid detection of fire and automatic start of extinguishing. This minimizes the spread of fire and limits potential damage to the production plant. It is this automation and immediate response that make this system irreplaceable in the context of ensuring continuity of production.

Studies show that companies that have implemented advanced fire extinguishing systems have seen their number of major downtimes related to fire hazards fall by over 60%. This means that investing in this type of technology can bring tangible financial benefits, as well as increase employee safety.

In addition to quickly extinguishing a fire, sprinkler systems reduce the risk of secondary damage to equipment and infrastructure. This allows for a quicker resumption of production after an incident. Companies that have invested in these systems often emphasize their impact on minimizing interruptions in daily operations.

Modernization vs. Production Maintenance – Best Installation Practices

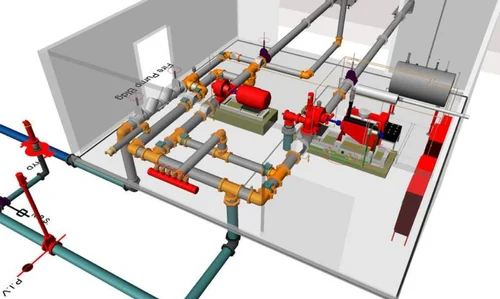

Each fire protection system should be adapted to the specifics of the plant. Proper installation of sprinkler systems and, of course, prior design both effectively protect against fire and ensure efficient operation without the need for long-term downtime during their installation or modernization.

When upgrading, it is good to follow a few important rules:

- [u]scheduling work outside production hours[/u] – reduces the risk of disruptions in production processes;

- [u]cooperation with experienced specialists[/u] – ensures proper adaptation of the system to the technical requirements of the facility;

- [u]regular inspections and maintenance[/u] – ensure that the system will function efficiently when a threat occurs.

It is worth emphasizing that companies that take care of regular maintenance of their installations have significantly fewer cases of system failures. This translates into even greater minimization of interruptions in work.

Rapid response to fire hazards – important aspects of sprinkler system operation

The operation of sprinkler systems is based on a rapid response to temperature increases or smoke detection in the room. Unlike traditional fire extinguishing methods, sprinkler systems are activated only in the area affected by the fire. This limits losses and helps avoid downtime in other parts of the plant.

The high efficiency of extinguishing systems results from their advanced technology and the use of materials resistant to corrosion and other mechanical damage. This makes them reliable and safe in operation.

The ecological aspect is also important. Modern systems are designed to minimize water consumption during extinguishing. This translates into lower operating costs and more sustainable operation of the entire infrastructure.

Implementing sprinkler systems is an investment that brings many benefits, both financially and organizationally. Thanks to them, companies can effectively secure their production processes, ensuring minimization of interruptions and maintaining business continuity. Fire protection based on advanced technologies is today an indispensable element of every modern production infrastructure.