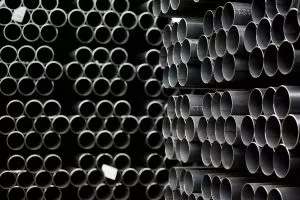

Prefabricated pipes for sprinkler systems – safety at the highest level

Modern fire protection systems require advanced technological solutions that will ensure effective operation at the most important moments. Fire sprinkler systems, using prefabricated components, guarantee quick assembly and reliability in extreme conditions. Prefabrication allows for precise adjustment of each component to the requirements of the project, minimizing the risk of assembly errors and extending the durability of the installation.

Prefabrication of pipelines – why is it worth choosing such a solution?

Prefabrication of fire protection pipelines is a process that revolutionizes the construction of fire protection systems. Because fire protection system components are prepared in controlled conditions, each component, from sprinkler pipes to connectors, meets the highest quality standards. The significant benefits of this solution include reduced assembly time, lower logistics costs and reduced installation errors. Sprinkler pipe prefabrication also allows for easy adaptation of components to specific design requirements, which ensures their compliance with applicable standards.

How do prefabricated pipes differ from traditional solutions?

Prefabricated fire protection pipes differ from traditional solutions in many ways. This in turn translates into their advantage in modern fire protection systems.

Manufacturing and assembly process

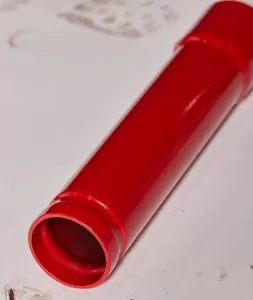

Sprinkler system installations require fitting and processing of elements directly on the construction site. This process is time-consuming and subject to errors resulting from weather conditions or inaccuracy in workmanship. Prefabrication, on the other hand, involves the initial preparation of pipes in controlled factory conditions, where they are cut, threaded, bent and protected against corrosion. Thanks to this, ready-to-install elements reach the construction site, which as a result shortens the installation time and minimizes the risk of errors. Precision and quality of workmanship Prefabrication of installation elements in terms of their production takes place using advanced technologies, such as welding, powder coating or 3D bending. This allows for achieving high precision of workmanship and uniform quality of each element. In traditional methods, where many operations are carried out manually on the construction site, it is more difficult to achieve such accuracy and repeatability. Anti-corrosion protection Prefabricated pipes are subjected to corrosion protection processes already at the production stage. As a result, this increases their resistance to moisture and other environmental factors. In traditional installations, this protection is often applied only after assembly, which can be less effective and durable. Design flexibility Comprehensive prefabrication of pipelines allows for the selection of these elements with specific diameters, thicknesses and shapes, thanks to which we gain greater freedom in designing fire protection systems adapted to the specific requirements of the facility. In traditional solutions, such adaptation can be more difficult and time-consuming.

Advanced Technologies for Prefabrication of Fire Pipes

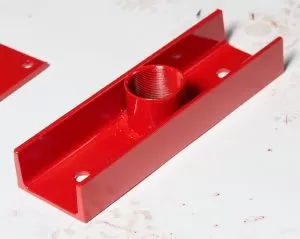

The prefabrication process of fire pipes is based on modern technologies that ensure high quality and durability of the installation. Important stages of this process include:

- [u]precise pipe cutting[/u] – adjusting the pipe length to the project requirements, making installation easier and material waste completely minimized;

- [u]grooving and threading[/u] — preparation of pipe ends in such a way as to enable the use of fittings from renowned manufacturers, which ensures tightness and reliability of connections;

- [drilling holes and welding of nozzles] — precise drilling of holes for overlay nozzles and their solid welding;

- [u]anti-corrosion protection[/u] – the use of methods such as powder coating to protect pipes against corrosion and extend their service life.

Thanks to these technologies, prefabrication of steel pipelines allows for the preparation of pipes of various diameters and thicknesses, which gives freedom in designing and adapting the installation to the specific needs of the facility. The use of advanced prefabrication methods, such as welding, powder coating or 3D pipe bending, ensures high quality of workmanship and durability of fire protection systems. The use of modern technologies in the prefabrication of fire protection pipes translates into assembly efficiency, cost reduction and operational reliability of fire protection systems.

Pipe prefabrication and compliance with fire safety standards

Prefabrication of pipelines for fire protection systems in our company is carried out in compliance with the highest standards of compliance with legal and technical standards in force in Poland, which ensures fire safety and use, and also guarantees full acceptance by technical supervision authorities. Design and production processes are based on detailed guidelines included in the Fire Protection Act, as well as the Regulation of the Minister of Internal Affairs and Administration regarding fire protection of buildings, as well as on the requirements included in the PN-EN 12845:2016-11 standards, which regulate the design, installation and maintenance of automatic sprinkler devices. The prefabrication of pipelines for sprinkler systems offered by our team also meets the specifications specified in the PN-EN 12259-1:2001 standards, guaranteeing the appropriate quality and functionality of sprinklers. Prefabricated elements of our installations, thanks to strict adherence to these regulations, are not only durable and effective, but also fully adapted to the specific requirements of the facilities in which they are installed. This allows for compliance with legal regulations, as well as for obtaining the highest level of safety in each implementation.

Reduced assembly time with prefabricated pipes

Prefabricated pipelines significantly speed up the installation process of fire protection systems. Components delivered to the construction site are ready for assembly, which eliminates the need for additional work such as welding or cutting pipes on site. Thanks to this, hydrant installations, including fire protection, can be carried out efficiently, reducing downtime and labor costs.

What types of buildings are best suited for fire sprinkler systems?

Sprinkler systems provide effective protection in a variety of facilities. Their application includes both commercial buildings, such as shopping malls, office buildings and hotels, as well as residential and industrial facilities, including production halls, warehouses and logistics centers. Thanks to the flexibility of design, it is possible to adapt sprinkler systems to the specific requirements of each facility, regardless of its size or purpose. Prefabricated sprinkler pipes play an important role here, enabling precise adjustment of the installation to the spatial layout of the building, which translates into the efficiency and reliability of the system. An integral element of these installations are fire pumping stations, which ensure a constant and adequate flow of water, necessary for the effective operation of sprinklers in the event of a fire hazard. As a result, comprehensive sprinkler systems, based on prefabricated components, offer high fire protection efficiency, adapted to the individual needs and specificity of the protected facilities.

The Most Common Pipe Installation Mistakes. How to Avoid Them?

When installing pipes in fire protection systems, mistakes are often made that can significantly reduce the effectiveness and reliability of the installation. The most common problems include:

- Improper fitting of elements: Lack of precision in connecting pipes can lead to leaks, which in the event of a fire results in insufficient water pressure and limited extinguishing efficiency.

- Lack of proper corrosion protection: Unprotected pipes are susceptible to corrosion, which weakens their structure over time and can lead to system failure.

- Incorrect selection of materials: The use of pipes with inappropriate technical parameters may result in their damage under the influence of high temperature or pressure.

- Incorrect pipe layout: Incorrect pipe routing can lead to delays in delivering extinguishing agent to the fire site, reducing the effectiveness of the system.

To avoid these problems, it is worth using the services of professionals offering prefabricated sprinkler pipes. The prefabrication process includes precise cutting, threading and anti-corrosion protection of the pipes. What’s more, prefabricated elements are tested before delivery to the construction site, which minimizes the risk of unforeseen problems during installation. By choosing our solutions, you can be sure that your fire protection installation will be durable, safe and effective in operation.

Comprehensive sprinkler systems for your facility

Our offer includes advanced sprinkler systems that meet the highest standards of safety and reliability. We offer comprehensive fire protection solutions, including pipe prefabrication services and installation design, but also sprinkler system service and comprehensive technical support at every stage of project implementation. Our fire sprinkler systems have been designed with maximum efficiency and adjustment to the individual needs of each client in mind. By using modern technologies and the highest quality materials, we guarantee that the provided installation will function flawlessly in all conditions. Don’t wait for a threat to appear. Contact us today to plan a fire protection system that will ensure the safety of you, your employees and property. We offer free consultations, during which our experts will answer all your questions and present a solution perfectly tailored to the specifics of your facility.